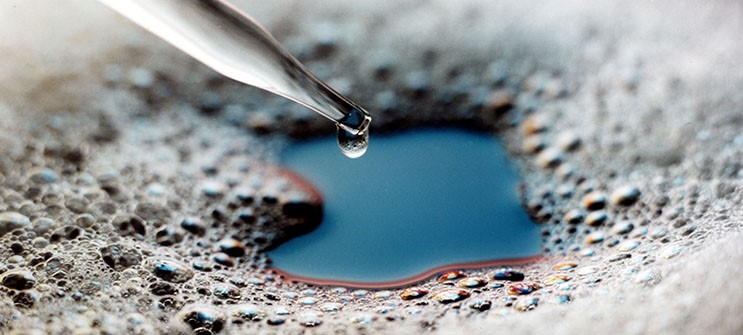

In the aeration tank, because the air is bulged from the inside of the aeration tank, and the microorganisms in the activated sludge will generate gas in the process of decomposing the organic matter, so a large amount of foam will be generated inside and on the surface of the sewage in the aeration tank. These foams will continue to accumulate on the surface and have a serious impact on the entire water treatment process. Silicone defoamer has proved to be the most ideal material in this process.

Water is the source of life

Access to clean and hygienic water every day is a need for each of us. Our demand for water resources has continued to rise for a long time. The more products we produce, manufacture, consume and discard, the more water we use.

It is our common responsibility to reduce waste of water resources and water pollution, and to improve the efficiency of wastewater treatment and achieve clean water circulation is the direction of our efforts.Foam can have serious impact on wastewater treatment processes

Industrial sewage contains high content of organic pollutants, heavy metals, pathogenic microorganisms and other substances, so three-stage wastewater treatment is required, and three processes of physical treatment, chemical treatment and biological treatment are generally used.

The basic process is as follows:

In the aeration tank, because the air is bulged from the inside of the aeration tank, and the microorganisms in the activated sludge will generate gas in the process of decomposing the organic matter, so a large amount of foam will be generated inside and on the surface of the sewage in the aeration tank.

These foams will continue to accumulate on the surface and have a serious impact on the entire water treatment process, such as:

◆Excessive foam reduces the water storage capacity of the aeration tank and reduces the efficiency

◆Foam affects the efficiency of sewage treatment by microorganisms in activated sludge

◆The foam is carried to the next process, which affects the secondary precipitation and causes overflow, which in turn causes further pollution.

◆Therefore, it is necessary to control and eliminate the foam in the aeration tank!

Silicone defoamer proves to be the most ideal material in this process

◆High defoaming efficiency of silicone defoamer

◆The physiological inertness of silicone materials will not cause negative harm to microorganisms

◆Compared with other kinds of defoamer, silicone has lower consumption of BOD and COD, and adding silicone defoamer has the least effect on the increase of BOD and COD

◆The wide range of application of silicone defoamer makes it have excellent defoaming and anti-foaming performance in different environments.

Advantages of foam control agents include:

◆Long-lasting foam control at all stages of the water purification process;

◆Silicone Antifoam can also exert high-efficiency foam control performance in the case of very small dosage;

◆Help water treatment plants improve process reliability;

◆Exhibits excellent dispersion performance in aqueous medium, so organic silicone defoaming agent is very easy to use;

◆Suitable for a variety of industrial media and a wide range of pH values;

◆Extremely low chemical oxygen demand (COD), very environmentally friendly;

◆It has long-term storage stability.

In the water treatment application industry, Silicone Antifoam is suitable for foam generated by different active substances, and has a wide range of pH and temperature, and also improves the long-lasting foam suppression performance. The dilution ratio can be increased, and a good foam control effect can be achieved at a very low dose, which enhances the process reliability of the sewage treatment process.

"Persisting in ""High high-quality, Prompt Delivery, Competitive Price"", we now have established long-term cooperation with consumers from equally abroad and domestically and get new and old clients' substantial comments for Top Grade China Papermaking Spreading Coating Defoamer, Our intention is ""blazing new floor, Passing Value"", inside the long term, we sincerely invite you to increase up with us and generate a vibrant long term together!

Top Grade China cleanwater Papermaking Silicone Defoamer,Papermaking Defoaming Agent, Paper, Supplement: 30% Silicone Chemical Silicon/Organic Pulp; 12.5% Silicone Used in Wastewater Treatment,Textile printing, paste, ink formulation process, for foam generated when printing scraper patterns in fabrics,We are eager to cooperate with foreign companies which care much on the real quality, stable supply, strong capability and good service. We can give the most competitive price with high quality,because we have been much MORE Specialist. You are welcomed to visit our company at any time.

Excerpted from BJX.

Post time: May-21-2022